12330 cub.mtr Concrete Batching Plant

30 cub.mtr Concrete Batching Plant

Product Description

The Batching plants are available in various capacities ranging from 30m3 to 120m3 per hour of compacted concrete output and designed for operations under extreme conditions with highest performance. Special Batching plant designs are available for dam construction and precast manufacturers. The design can adopt Ice dosing, Microsilica dosing and some special additives very easily.

Specification

| Model & Specifications | Unit | BP 30 |

|---|---|---|

| Mixer Type | – | Planetary |

| Discharge canacity (Concrete) | cub.mtr/min | 0.5 |

| Capacity of mixer (Dry Filling) | lit | 750 |

| Compacted output / batch | lit | 500 |

| Bin Model | nos | 4 Compartment.Bins |

| Bin Storage Capacity | – | 10 cub.mtr each 2.5 cub mtr |

| Aggregate Loading Capacity | kg | 950 |

| Aggregate Loading Height | mtr | 3.6 |

| Aggregate Loading Bin to Mixer | – | Chevron Belt Conveyor |

| Cement Loading System | – | Screw Conveyor |

| Cement Loading Hopper capacity | Kg | 1500 |

| Cement Weighing Hopper capacity | kg | 125 |

| Water System | – | Auto Cut Off |

| Water Tank Capacity | lit | 112 |

| Admixture | – | Load Cell/Timer Based |

| Concrete Discharge Height | mtr | 1.65 |

| Concrete Discharge Height-4.2mtrs (Optional) | – | Extended feeding conveyor/ Extra Throw belt conveyor / Skip hoist |

| Control Panel | – | PLC Type/SCADA Optional |

| Maximum Operational Load | Hp | 55 |

| D.G. Set Required | KVA | 82.5 |

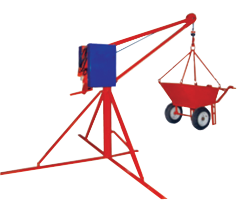

Other Products

Copyright © 2024 VPG Buildwell India Private Limited | All Rights Reserved

Web Solutions by AES Technologies (India) Pvt. Ltd.

98652 10000, 80156 60000

98652 10000, 80156 60000